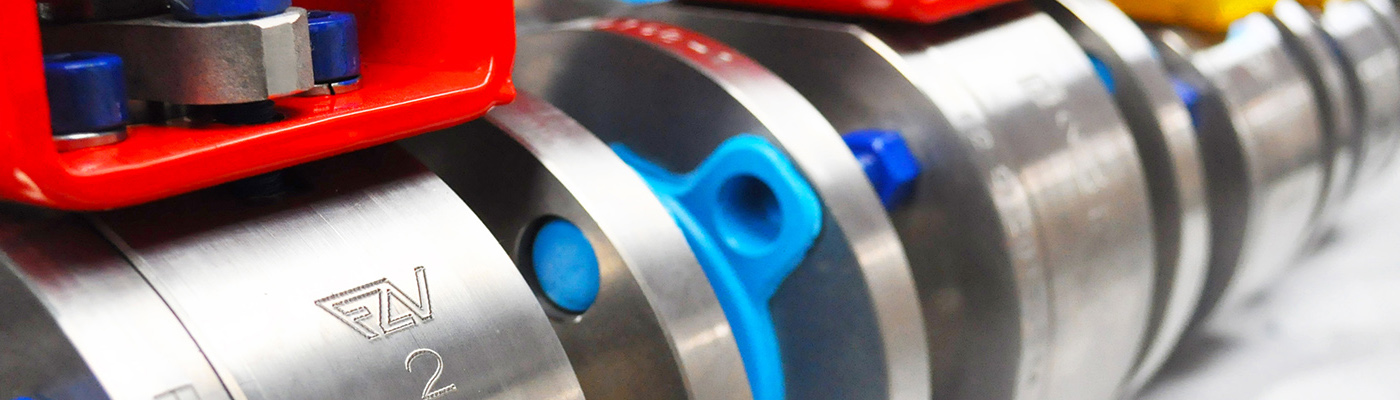

Dual Plate Check Valve

Technical parameters and characteristics:

Product type | ON/OFF |

Product description | Dual Plate Check Valve |

Model | Hn46H-Dual Plate Check Valve |

Nominal diameter | NPS 2”~48”(DN50~DN1200) |

Operating temperature | -29℃~593℃(the range of service temperature may vary for different materials) |

Nominal pressure | CLASS 150~2500 (PN20~PN420) |

Material | Main material: A216 WCB、WCC; A217 WC6、WC9、C5、C12、C12A、CA15; A351 CF8、CF8M、CF3、CF3M、CF8C、CN3MN、CK3MCUN、CN7M; A352 LCB、LCC; A494 CW-6MC、CU5MCuC、M35-1;A890 4A(CD3MN)、5A(CE3MN)、6A(CD3MWCuN); ASME B 148 C95800、C95500, etc. |

Design standard | API 6D、API 594、ASME B16.34 |

Structural length | API 6D、API 594 |

Connecting end | ASME B16.5、ASME B16.47、GB/T 9113 |

Test standard | API 598、ISO 5208、GB/T 26480、GB/T 13927 |

Operation method | The valve clack is automatically opened and closed under the medium force to prevent flowing to another direction. |

Application fields | For application in fields such as electric power industry, petroleum refining, petrochemical engineering, offshore oil, tap water engineering in urban construction, chemical engineering, etc. |

Other remarks 1 | The sealing faces of valve seat and valve clack are build-up welded with hard alloy to improve the erosion resistance and extend the service life of valve. |

Other remarks 2 | Short closing travel of valve clack, and small impact at valve closing; short structural length, most suitable for positions with limited mounting space |

Other remarks 3 | Suitable for medium backflow prevention in pipeline or device |

Other remarks 4 | Built-in pin roll, without external leakage point |

Other remarks 5 | Due to loading of spring, the valve clack can move flexibly without jamming, and has a good sealing performance. |