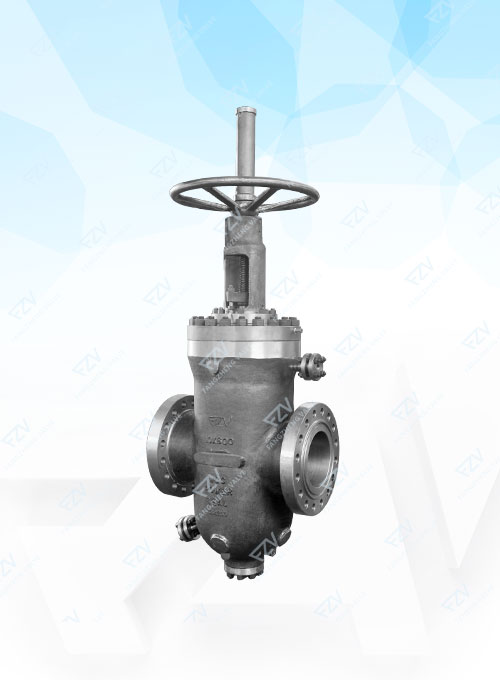

Expanded Gate Valve

Technical parameters and characteristics:

Product type | ON/OFF |

Product description | Expanded Gate Valve |

Model | Zpc48H-Expanded Gate Valve |

Nominal diameter | NPS 2”~30”(DN50~DN750) |

Operating temperature | -196℃~593℃(the range of service temperature may vary for different materials) |

Nominal pressure | CLASS 150~2500 (PN20~PN420) |

Material | Main material: A216 WCB、WCC; A217 WC6、WC9、C5、C12、C12A、CA15; A351 CF8、CF8M、CF3、CF3M、CF8C、CN3MN、CK3MCUN、CN7M; A352 LCB、LCC; A494 CW-6MC、CU5MCuC、M35-1; A890 4A(CD3MN)、5A(CE3MN)、6A(CD3MWCuN); ASME B 148 C95800、C95500, etc. |

Design standard | API 600、ASME B16.34、GB/T 12234、GB/T 12224 |

Structural length | ASME B16.10、GB/T 12221 |

Connecting end | ASME B16.5、ASME B16.47、ASME B16.25、GB/T 9113、GB/T 12224 |

Test standard | API 598、ISO 5208、GB/T 26480、GB/T 13927 |

Operation method | non-elevating hand wheel, bevel gear, motor drive unit, pneumatic drive unit |

Application fields | For application in fields such as electric power industry, tap water engineering in urban construction, chemical engineering, etc. |

Other remarks 1 | The sealing faces of valve seat and valve clack are build-up welded with hard alloy to improve the erosion resistance and extend the service life of valve. |

Other remarks 2 | SS+ graphite or metallic seal or pressure self-sealing is adopted between valve body and bonnet for reliable sealing |

Other remarks 3 | Rising stem structure, making the valve switch position be clear at a glance |

Other remarks 4 | The valve stem thread will not come into contact with the medium, so the corrosion of medium to the thread is reduced. |

Other remarks 5 | Small switching moment, reliable sealing |

Other remarks 6 | The self-sealing parallel double-plate and the stretching type parallel double-plate structures are adopted, so the valve would not jam due to the impact of cold or hot medium. |

Other remarks 7 | Small flow resistance, high flow capacity and good flow characteristics |

Other remarks 8 | Through improving the structural design and selecting reasonable packing structure and qualified packing supplier, the valves can meet the Class A sealing test requirements of ISO 15848 FE. |